Stainless steel materials are widely used in architecture, industry, home appliances, automobiles and other fields due to their excellent corrosion resistance and aesthetics. In order to meet the needs of different application scenarios, the surface of stainless steel can be treated in a variety of ways to form a distinctive surface type. This article will introduce several common types of stainless steel surface treatment and its characteristics.

2B

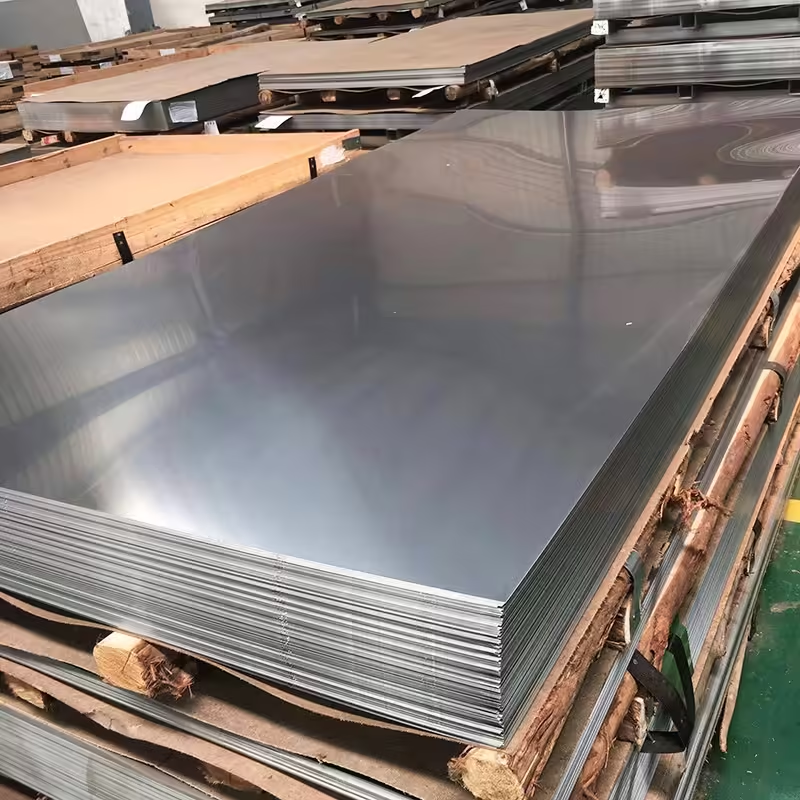

Stainless steel 2B finish is a common stainless steel surface treatment usually used in industrial and manufacturing industries. It is a surface treatment after cold rolling, annealing and removal of oxide skin.2B surface has the following characteristics:

Matte Surface: 2B surface has a smooth, matte appearance that is smoother than the No.1 surface, but not as bright as the BA (Bright Annealed) surface.

Good Corrosion Resistance: The 2B surface is usually applied to stainless steel materials such as 304, 316, etc. during the manufacturing process and has good corrosion resistance.

Wide range of applications: 2B surfaces are widely used in a variety of industrial equipment, building materials, kitchenware and medical equipment.

No.1

Stainless steel No.1 surface is a type of surface finish that is formed after hot rolling and annealing. The No.1 surface is typically rougher compared to the 2B surface and is primarily used for industrial and structural applications. Its key features include:

Rough Matte Surface: No.1 surface is formed after hot rolled stainless steel is annealed and de-oxidised, the surface is rougher and presents a uniform matte effect.

Thicker: Because it is a hot rolled product, No.1 surface stainless steel sheets are usually thicker and are suitable for application scenarios that require strength and durability.

BA

Stainless steel BA (Bright Annealed) surface is a bright annealed stainless steel surface type that is highly lustrous and reflective. The following are the main characteristics of BA surfaces:

High gloss: BA surfaces are bright annealed to a very smooth surface with a mirror-like lustre and reflective effect. This makes the BA surface ideal for applications in products with high demands on appearance.

NO.4

Stainless steel No.4 finish is a common brushed finish surface with a uniform fine texture and is a very popular type of finish for industrial and decorative applications. Below are the key features of the No.4 surface:

Fine brushed texture: The No.4 surface is mechanically polished to produce a fine, long straight line or brushed texture, which usually has a matte finish with a uniform and directional texture.

Anti-fingerprint and anti-glare: Thanks to its fine texture, the No.4 surface shows relatively few fingerprints and smudges and reflects light without strong glare, making it more practical in certain lighting conditions.

Mirror

Stainless steel mirror finish is a highly glossy and reflective stainless steel surface type obtained by precision polishing, often also known as 8K finish. The following are the main characteristics of a mirror finish:

Highly lustrous and reflective: Mirror surfaces are polished through multiple polishing processes to achieve a high degree of luminosity, with a smooth mirror-like surface that reflects objects clearly. This surface is often referred to as “8K” or “mirror stainless steel”.

Aesthetics: Mirror surfaces are ideal for decorative applications due to their high reflectivity and smooth texture, enhancing the visual appeal and texture of the product.