Stainless steel sheets are widely used in various industries due to their durability and versatility. Among them, brushed finish stainless steel sheets stand out for their unique aesthetic and functional properties, making them a favorite in design and architectural fields. Therefore, this article explores the features, processes, applications, and maintenance of brushed stainless steel sheets.

What is a Brushed Finish Stainless Steel Sheet?

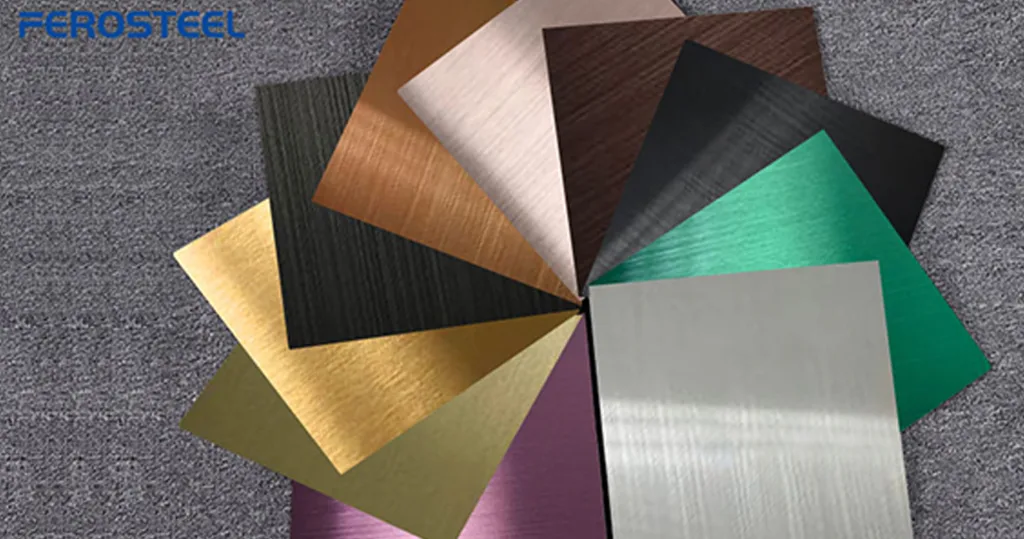

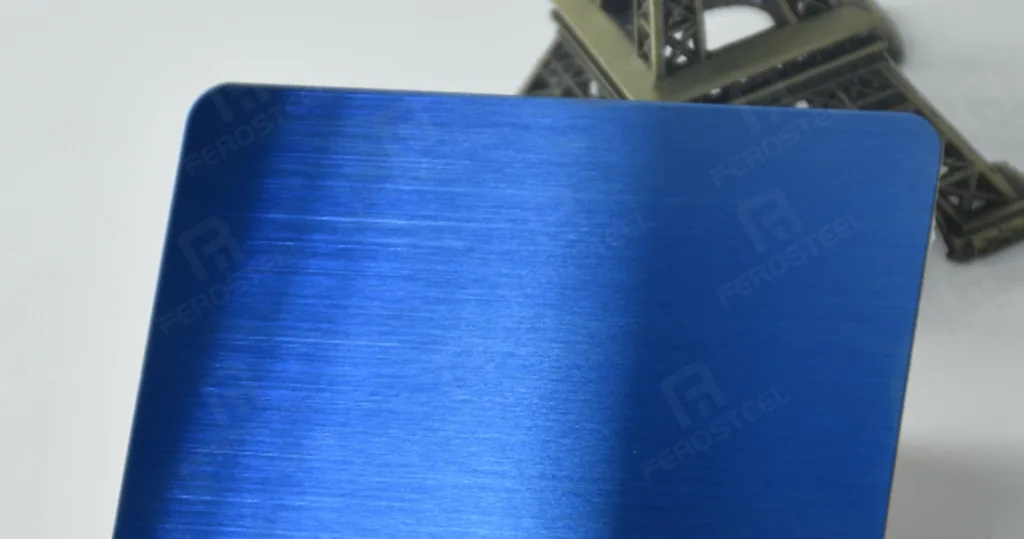

A brushed finish results from mechanical processing that creates uniform textures on the surface of stainless steel sheets. These textures usually appear as straight lines, waves, or arcs, giving the sheet a matte metallic look. Consequently, brushing not only enhances the decorative appeal but also improves scratch resistance.

Manufacturing Process of Brushed Stainless Steel

The production of brushed stainless steel typically involves the following steps:

- Surface Cleaning: Workers clean the sheet to remove oil stains and oxides.

- Brushing Process: Operators use sanding belts, grinding wheels, or brushes to grind the surface, creating uniform textures.

- Surface Protection: Transparent protective films are applied to prevent damage to the brushed texture.

As a result, these steps ensure that the brushed finish retains its aesthetic and functional qualities.

Advantages of Brushed Stainless Steel

- Elegant Appearance: The brushed texture enhances the visual appeal, offering a modern and premium feel.

- Fingerprint Resistance: Compared to mirror-finish stainless steel, the brushed surface resists fingerprints and smudges more effectively.

- Durability: The brushing process reduces surface glare and minimizes the visibility of minor scratches.

- Easy Maintenance: Dirt and stains can be wiped off easily with a damp cloth.

Thus, these advantages make brushed stainless steel a practical and stylish choice for various applications.

Applications

Brushed finish stainless steel serves in the following areas:

- Architectural Design: Walls, ceilings, and elevator interiors feature this material.

- Household Appliances: Panels for refrigerators, dishwashers, ovens, and more often use brushed finishes.

- Public Infrastructure: Bus shelters, vending machines, and handrails benefit from its durability and aesthetic.

- Commercial Spaces: Counters, display racks, and storefront decorations frequently incorporate brushed stainless steel.

Furthermore, its versatility ensures that it fits seamlessly into diverse environments.

Maintenance Tips for Brushed Stainless Steel

Although brushed stainless steel is highly durable, proper maintenance can extend its lifespan and retain its appearance:

- Regular Cleaning: Use a neutral cleaner and soft cloth to wipe the surface, avoiding abrasive cleaning tools.

- Avoid Chemical Damage: Keeping the material away from strong acids or alkalis prevents corrosion.

- Timely Repairs: Minor scratches can be restored through re-brushing processes.

In addition, consistent care will ensure the material remains attractive and functional over time.

Conclusion

Brushed finish stainless steel sheets offer distinctive decorative effects, superior performance, and wide-ranging applications. From modern architecture to household use, and from commercial spaces to public infrastructure, this material combines functionality with artistry. For a choice that is both aesthetically pleasing and practical, brushed finish stainless steel sheets stand out as an excellent option!