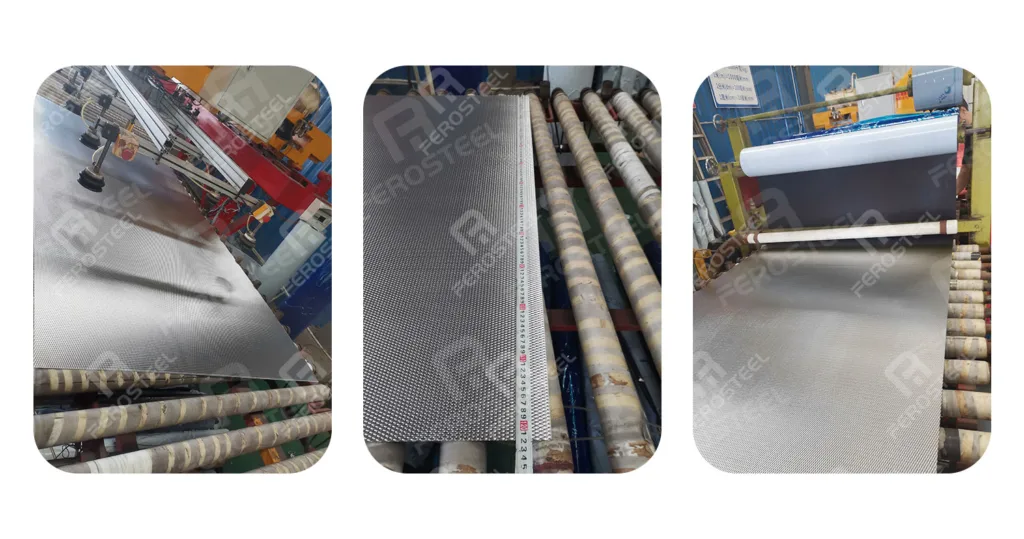

Stainless steel stamped decorative sheets are a popular choice in modern architecture, interior design, and manufacturing. These sheets are durable, corrosion-resistant, and easy to clean, making them perfect for a wide range of applications. Among the different patterns available, 5WL and 6WL are two of the most commonly used. Let’s explore their differences, features, and uses.

1. What Are Stainless Steel Stamped Decorative Sheets?

Stainless steel stamped sheets are created by pressing various patterns into the surface of the stainless steel. These patterns enhance both the appearance and the functionality of the sheets, providing durability and slip resistance. Popular designs include hairline (HL), No.4, mirror finishes, and wave patterns like 5WL and 6WL.

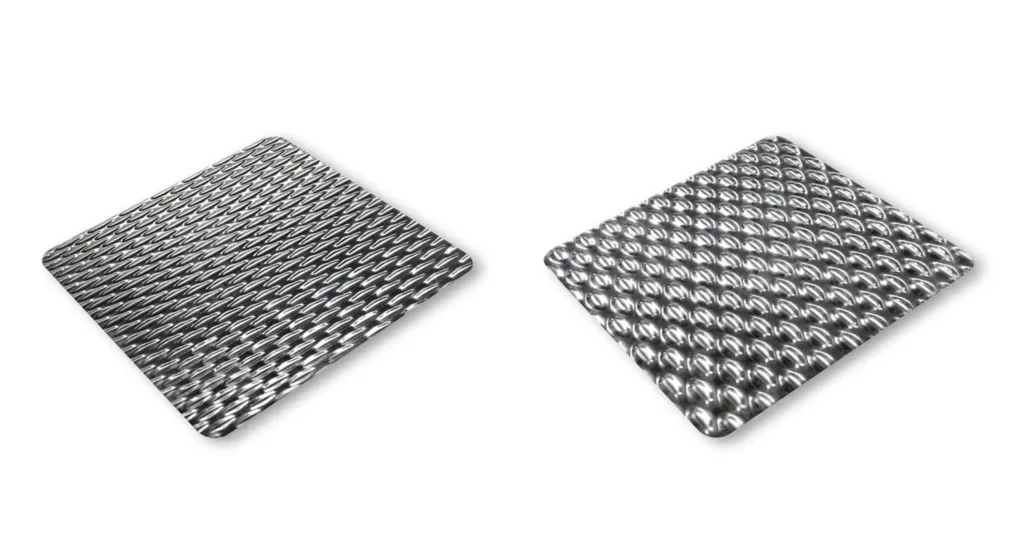

2. 5WL Stainless Steel Stamped Decorative Sheet

2.1 Characteristics

The 5WL pattern creates smooth, shallow waves. This subtle texture gives the sheet a soft, refined look. The waves are gentle, adding depth without overwhelming the design. The surface reflects light in different ways, making the sheet dynamic yet understated.

2.2 Applications

Thanks to its subtle wave pattern, 5WL works well in spaces that call for a modern, sophisticated style. You’ll often find it in:

- Interior Design: Walls, ceilings, and elevator interiors.

- Building Facades: Cladding that enhances a building’s modern look.

- Public Transport: Subway cars and trains, where both durability and style matter.

2.3 Advantages

- Elegant Aesthetic: The soft wave pattern suits minimalist and contemporary interiors.

- Durability: Stainless steel resists corrosion, making it perfect for indoor and outdoor applications.

- Slip Resistance: The texture offers extra grip, making it useful for floors and high-traffic areas.

3. 6WL Stainless Steel Stamped Decorative Sheet

3.1 Characteristics

The 6WL pattern features deeper, more pronounced waves. This texture creates a bolder, more dramatic appearance. The deeper waves make the sheet stand out, which is ideal for projects that require a striking design.

3.2 Applications

The deeper, bolder texture of 6WL makes it suitable for projects that need to make a visual impact. Common applications include:

- High-End Commercial Spaces: Hotel lobbies, office buildings, and high-end retail stores.

- Building Exteriors: Creating dramatic, artistic facades.

- Transport Design: Used in vehicles like luxury cars, buses, and boats.

3.3 Advantages

- Bold Aesthetic: The deeper waves deliver a strong visual impact.

- Versatility: Combines aesthetic appeal with durability.

- Unique Look: Perfect for projects that want to stand out with a distinct design.

4. Key Differences Between 5WL and 6WL

| Feature | 5WL | 6WL |

|---|---|---|

| Wave Depth | Shallow, smooth waves with a subtle effect | Deep, pronounced waves with a striking visual impact |

| Visual Effect | Soft, understated, modern look | Bold, dynamic, and attention-grabbing |

| Common Uses | Interior walls, ceilings, facades | High-end commercial spaces, transport, bold exteriors |

| Functionality | Decorative, durable, slip-resistant | Strong visual impact, durable, slip-resistant |

5. Choosing Between 5WL and 6WL Sheets

The choice between 5WL and 6WL depends on your project’s design goals. If you prefer a sleek, minimal look, go with 5WL. If you want a more bold and striking effect, 6WL is the better option.

Considerations:

- Design Style: Choose 5WL for a more subtle, elegant feel. Opt for 6WL if you want a bold, dynamic look.

- Functionality: Both sheets offer durability, but 6WL’s deeper texture may provide additional slip resistance.

- Budget: 6WL may cost a little more due to its more complex texture.

6. Conclusion

Both 5WL and 6WL stainless steel stamped sheets have their unique advantages. The 5WL sheet works well for creating a refined, minimalist environment, while the 6WL sheet makes a bold statement with its dynamic design. Understanding these differences helps you choose the right material for your project, whether it’s for interior design, building facades, or transportation.