Hammered metal sheets are known for their distinctive, irregular textured surfaces, making them a favorite choice in architecture, interior design, and artisanal crafts. Created by striking metal surfaces with a hammer—either manually or mechanically—these sheets achieve a beautiful pattern of indentations that enhance both visual appeal and functionality. This article explores hammered sheets in detail, from their characteristics and manufacturing processes to applications and maintenance tips.

What Are Hammered Metal?

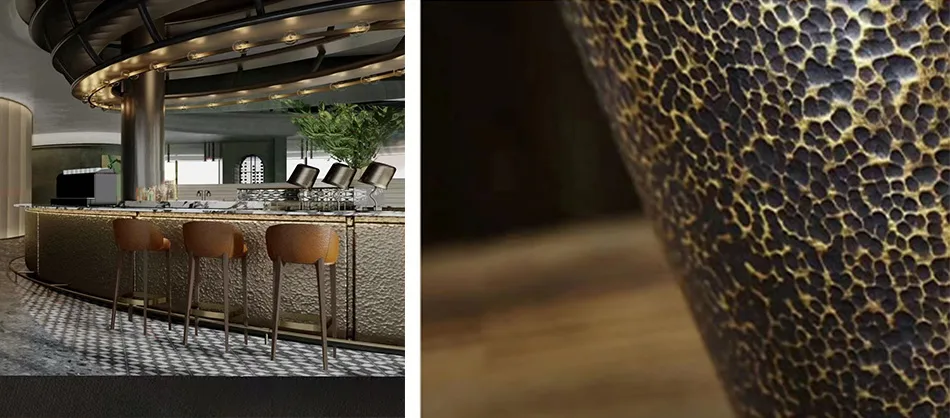

Hammered metal sheets are hammered panels featuring uneven, pitted surfaces achieved through repetitive hammering. They are widely used for both decorative and functional purposes. Common materials include stainless steel, copper, brass, and aluminum. These sheets can add a vintage or industrial touch to any space and are prized for their aesthetic and durability.

Key Features of Hammered Sheets

- Unique Textures

Hammering creates irregular divots, giving the metal a dynamic and tactile surface that stands out.- Durability

The hammering process increases the metal’s structural integrity, making it resistant to wear and tear.- Material Versatility

Hammered finishes can be applied to various metals, such as:

- Stainless Steel: Corrosion-resistant and ideal for harsh environments.

- Copper and Brass: Offer a warm, luxurious appearance.

- Aluminum: Lightweight and cost-effective.

- Customizability

Surface finishes like polishing, brushing, or oxidizing can be tailored to suit specific design styles.

How Hammered Metal Sheets Are Made

Producing hammered metal involves several key steps:

- Material Selection

Choose the appropriate metal based on the intended application. Stainless steel is ideal for moisture-prone areas, while copper adds a warm, artistic flair.- Cutting and Shaping

The metal is cut to the desired size and prepared for hammering.- Hammering

- Hand Hammering: Provides a more artisanal, irregular texture, perfect for custom projects.

- Mechanical Hammering: Ensures consistency for large-scale production.

- Surface Treatment

Options include:

- Polishing: Creates a shiny, reflective surface.

- Oxidation: Adds an aged, rustic look.

- Coating: Enhances corrosion resistance.

Applications of Hammered Metal Sheets

Hammered sheets are versatile and find use across numerous industries:

1. Architecture and Building Design

- Exterior cladding for buildings, adding texture and character to facades.

- Interior wall panels and ceilings, providing an industrial or luxurious feel.

2. Interior Design

- Backsplashes in kitchens, blending functionality with elegance.

- Accent walls in living rooms, creating visual depth.

3. Furniture and Lighting

- Tabletops and cabinet doors with hammered metal finishes offer a sophisticated touch.

- Used in lighting fixtures, such as lampshades, to create intriguing light diffusion.

4. Art and Craftsmanship

- Crafting vases, sculptures, or decorative trays with unique textures.

- Adding a personalized touch to bespoke designs.

5. Commercial Spaces

Hotels, restaurants, and retail stores use hammered metal to create striking design elements.

Advantages of Hammered Sheets

- Aesthetic Appeal

The textured finish adds depth, making them visually captivating.- Durability

The hammering process strengthens the metal, enhancing its longevity.- Versatility

Adaptable to various styles, from modern industrial to rustic traditional.- Sustainability

Most metals used in hammered sheets are recyclable, aligning with eco-friendly practices.

Tips for Choosing Hammered Stainless Steel Metal Sheet

When selecting hammered metal, consider the following:

- Environment

For outdoor or moisture-prone areas, stainless steel is a better choice due to its resistance to rust. Indoors, copper or brass can provide a warmer aesthetic.- Finish Requirements

Decide between polished, brushed, or oxidized finishes based on design needs.- Supplier Reputation

Choose reputable suppliers to ensure quality and reliability.

Maintenance and Care

To maintain the beauty and functionality of hammered sheets, follow these tips:

- Regular Cleaning

Use a soft cloth and mild detergent to clean the surface. Avoid abrasive materials that could scratch the texture.- Prevent Rust

Apply a protective coating, especially for metals like copper or brass, to prevent oxidation.- Avoid Physical Damage

Minimize contact with sharp or heavy objects that could deform the hammered surface.- Polish Periodically

Restore the sheet’s luster by polishing it, especially if exposed to frequent handling.

Future Trends in Hammered Metal Sheets

As design preferences evolve, hammered sheets are poised to remain popular. Future developments may include:

- Innovative Materials

Incorporation of hybrid or composite metals to enhance strength and reduce weight.- Advanced Techniques

Combining hammering with laser cutting or etching for intricate designs.- Sustainability

Increased use of recycled metals to support eco-friendly initiatives.- Smart Integration

Application in smart homes, such as textured panels for sensor integration.

Frequently Asked Questions (FAQ)

Hammered metal are metal panels with textured, pitted surfaces achieved through hammering, often used for decoration and structural purposes.

Stainless steel, copper, brass, and aluminum are the most common materials.

Yes, especially stainless steel, which resists corrosion and weathering.

Absolutely. They can be tailored in terms of size, thickness, material, and surface finish.

Costs vary based on the material and manufacturing process. Stainless steel is typically more affordable than copper or brass.